FilterMag Industial Division

FILTERMAG INDUSTRIAL PRODUCTS

Reduce Wear • Extend Equipment and Engine Life • Protect Your Investment

FILTERMAG INDUSTRIAL PRODUCTS APPLICATIONS

IMPROVED OIL QUALITY - LONGER FLUID LIFE - PROVEN IN THE FIELD

FilterMag is proven effective in the laboratory and in extensive field service to remove particles that contribute to equipment wear.

Cleaner lubrication oil directly contributes to longer service life, reduced downtime, and lower maintenance costs

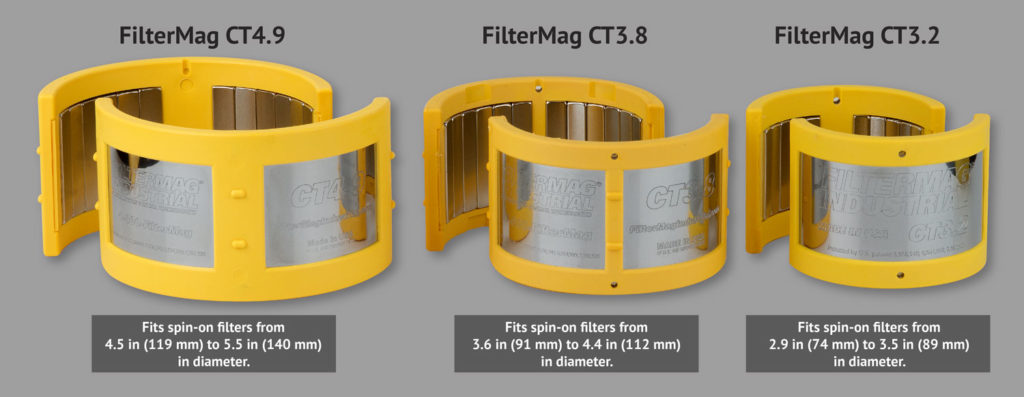

CT PRODUCTS FOR SPIN-ON-FILTERS

Spin-on Filters Use FilterMag CTs

1. POWERFUL, HEAT-RESISTANT NEODYMIUM ALLOY MAGNETS are engineered to focus a magnetic field inside your filter. Specifically formulated to remain effective in the most extreme environments, our magnets are guaranteed to remove particles from oil operating at up to 300ºF while most magnets start losing magnetism at 180ºF

2. PATENTED FLUXCON™ SHIELDING TECHNOLOGY stops magnetic flux which could damage electronic components. Not even a paper clip will stick to the outside of a FilterMag. Our FluxCon™ system also redirects a portion of that magnetic power back into the filter to increase filtration efficiency.

3. RUGGED FLEXIBLE FRAME encases and protects the elements of a FilterMag while providing enough flexibility to fit a range of filter diameters. Our proprietary design and materials are rated for temperatures from -40ºF to +300ºF (-40ºC to +150ºC).

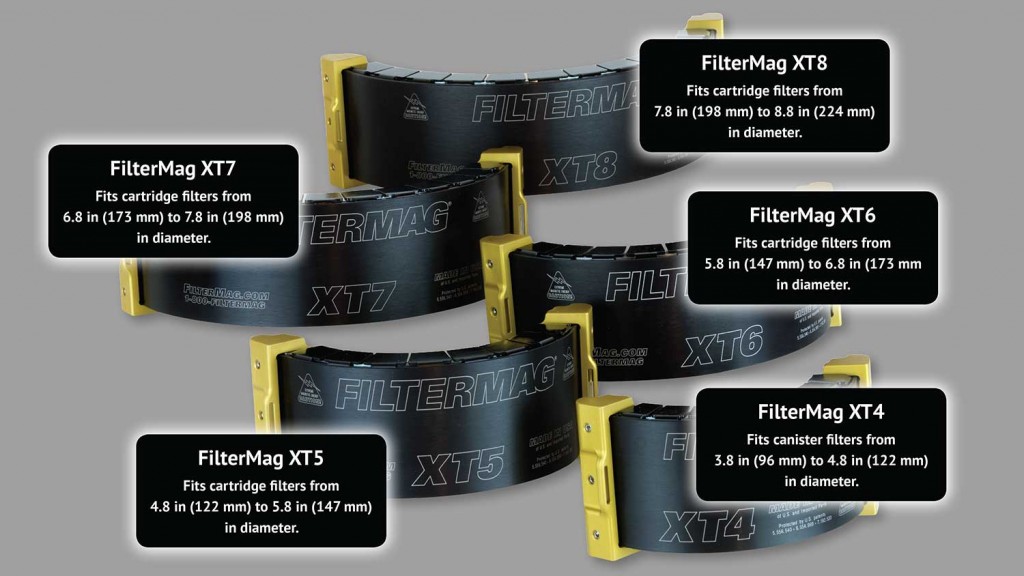

XT PRODUCTS FOR CARTRIDGE FILTERS

Fixed Cartridge Filters Use FilterMag XTs

1. EXTREMELY POWERFUL, HEAT-RESISTANT NEODYMIUM ALLOY MAGNETS are engineered to focus a magnetic field inside your filter through even the thickest canister walls. Specifically formulated to remain effective in the most extreme environments, our magnets are guaranteed to remove particles from oil operating at up to 300ºF while most magnets start losing magnetism at 180ºF.

2. SECURITY END CAPS integrate all the parts of a FilterMag XT while allowing enough flexibility to fit a range of filter housing sizes. Our proprietary anchoring technology ensures component integrity even under extended periods of extreme vibration. Built in slots for use with stainless steel band clamps allow attachment to aluminum filter housings or for redundant security when used in an overhead environment.

3. PATENTED FLUXCON™ SHIELDING TECHNOLOGY stops magnetic flux from emanating out the back of the FilterMag. Our FluxCon™ system also redirects a portion of that magnetic power back into the filter to increase filtration efficiency.

4. Rock Guards protect the magnets from damage.

5. Our proprietary design and materials are rated for temperatures from -40ºF to +300ºF (-40ºC to +150ºC).

FILTERMAG MAGNETIC DRAIN PLUGS - FILTER-MAG-PLUGS

There are 3 designs available:

1) Smooth Tube, or

2) Centering Fin Tubes, or

3) Enhanced Rod Tubes with Centering Fins

All our magnetic drain plugs capture & remove metal particles from your oil! Lowers your maintenance costs! Extends your equipment life! Filter-Mag-Plugs use powerful N42 neodymium magnets that are temperature rates from -40ºF to +300ºF (-40ºC to +150ºC). Self-Centering Fins (patent pending) provide easy installation, cleaner removal, and reduced thread cleaning prior to reinstallation. Enhanced Rod Tubes (patent pending) allow for Filter-Mag-Plugs to be used in close proximity to internal lubricated components when that is required by the equipment design. All Filter-Mag-Plugs are custom made to customer specifications on our Hass CNC lathe and mill.

1) Smooth Tube, or

2) Centering Fin Tubes, or

3) Enhanced Rod Tubes with Centering Fins

All our magnetic drain plugs capture & remove metal particles from your oil! Lowers your maintenance costs! Extends your equipment life! Filter-Mag-Plugs use powerful N42 neodymium magnets that are temperature rates from -40ºF to +300ºF (-40ºC to +150ºC). Self-Centering Fins (patent pending) provide easy installation, cleaner removal, and reduced thread cleaning prior to reinstallation. Enhanced Rod Tubes (patent pending) allow for Filter-Mag-Plugs to be used in close proximity to internal lubricated components when that is required by the equipment design. All Filter-Mag-Plugs are custom made to customer specifications on our Hass CNC lathe and mill.

- Magnetic Enhancement Rods help contain the magnetic field

- Self-Centering Fins provide easy installation, cleaner removal, and reduced thread cleaning prior to reinstallation

- Particle Channels hold more particles

MAGNETIC TUBE TYPES

1- SMOOTH

Plain smooth tube regular drain plugs

– Powerful N42 Rare Earth Neodymium Magnets

– Magnet Temperature Rating -40°F to 302°F (-40ºC to +150ºC)

– Custom Machined from 303 Stainless Steel (316 available)

– Magnet Temperature Rating -40°F to 302°F (-40ºC to +150ºC)

– Custom Machined from 303 Stainless Steel (316 available)

2- CENTERING FINS

Tubes with centering fins (patent pending)

– The fins keep the drain plug centered for easier threading. On larger diameter drain plugs they are required so the plug can be threaded into the oil reservoir.

– When the plug is removed the fins minimize the particles from contacting the threads in the reservoir. That minimizes the need for cleaning the threads before reinstalling the plug.

– When the plug is removed the fins minimize the particles from contacting the threads in the reservoir. That minimizes the need for cleaning the threads before reinstalling the plug.

3- CENTERING FINS WITH ENHANCEMENT RODS

The enhanced drain plugs with rods [all enhanced plugs also have centering fins, patent pending]

– The rods shrink the diameter of the magnetic field to approximately 1/4 the diameter of the non-enhanced plugs.

– For a 1″ magnet inside a smooth tube or fins only tube, the Filter-Mag-Plug needs to be 4″ away from internal gears. If the plug is less than 4″ away from the gear or internal component, the gear that is rotating through the field will become magnetized, particles will stick to the gear and caused increased wear.

– The Enhancement Rods shrink the magnetic field’s diameter and allow the drain plug to be 1″ from the gear or internal component and not magnetize the gear. The magnetic field is also enhanced between the rods, it is 3-5 times stronger which will capture and hold more particles.

– For a 1″ magnet inside a smooth tube or fins only tube, the Filter-Mag-Plug needs to be 4″ away from internal gears. If the plug is less than 4″ away from the gear or internal component, the gear that is rotating through the field will become magnetized, particles will stick to the gear and caused increased wear.

– The Enhancement Rods shrink the magnetic field’s diameter and allow the drain plug to be 1″ from the gear or internal component and not magnetize the gear. The magnetic field is also enhanced between the rods, it is 3-5 times stronger which will capture and hold more particles.

Features

Benefits

Smooth

Centering Fin

Centering Fins With Rods

N42SH Magnets

Powerful neodymium rare earth magnets

Powerful magnetic force

N42SH Magnets

N42SH Magnets

Temperature Rated -40°F to 302°F (-40°C-150°C)

They do not lose magnetic force in normal operating temperatures.

Reusable

Reusable-just remove, clean and reinstall. FMPs typically last the life of the equipment.

Minimum Magnetic force at the end of the tube

Made for easy particle removal, just wipe off captured particles towards the end of the tube.

Centering Fins

Allows powerful large diameter magnets to be used. Keeps tubes centered for easy thread starting

Centering Fins

Keeps threads cleaner. Captured particles have minimum contact with threads when removed.

Use in Close Quarters

Gears need to be far enough from the magnetic field to not be magnetized.

Internal Components?

A 1” diameter magnet used in a FMP requires gear clearance of:

4"

4"

1"

Smooth

Features

Benefits

N42SH Magnets

Powerful neodymium rare earth magnets

Powerful magnetic force

N42SH Magnets

N42SH Magnets

Temperature Rated -40°F to 302°F (-40°C-150°C)

They do not lose magnetic force in normal operating temperatures.

Reusable

Reusable-just remove, clean and reinstall. FMPs typically last the life of the equipment.

Internal Components?

4″ (A 1” diameter magnet used in a FMP requires gear clearance of)

Centering Fins

Features

Benefits

N42SH Magnets

Powerful neodymium rare earth magnets

Powerful magnetic force

N42SH Magnets

N42SH Magnets

Temperature Rated -40°F to 302°F (-40°C-150°C)

They do not lose magnetic force in normal operating temperatures.

Reusable

Reusable-just remove, clean and reinstall. FMPs typically last the life of the equipment.

Centering Fins

Allows powerful large diameter magnets to be used. Keeps tubes centered for easy thread starting

Centering Fins

Reusable-just remove, clean and reinstall. FMPs typically last the life of the equipment.

Internal Components?

4″ (A 1” diameter magnet used in a FMP requires gear clearance of)

Centering Fins with Rods

Features

Benefits

N42SH Magnets

Powerful neodymium rare earth magnets

Powerful magnetic force

N42SH Magnets

N42SH Magnets

Temperature Rated -40°F to 302°F (-40°C-150°C)

They do not lose magnetic force in normal operating temperatures.

Reusable

Reusable-just remove, clean and reinstall. FMPs typically last the life of the equipment.

Centering Fins

Allows powerful large diameter magnets to be used. Keeps tubes centered for easy thread starting

Centering Fins

Reusable-just remove, clean and reinstall. FMPs typically last the life of the equipment.

Use in Close Quarters

Gears need to be far enough from the magnetic field to not be magnetized.

Internal Components?

1″ (A 1” diameter magnet used in a FMP requires gear clearance of)

WATERMAG

WaterMag—Molecular Water Absorber